Efficient Ways to Manage Inventory in 2024

Efficient Ways to Manage Inventory in 2024

In the world of business, efficient inventory management is crucial for success. Small businesses face unique challenges when managing inventory, from limited resources to space constraints. Understanding the basics of how to manage inventory is essential for maintaining a healthy supply chain and meeting customer demands.

Importance of Efficient Inventory Management

Maintaining a well-oiled and efficient inventory management system is not just a logistical exercise. It's a strategic necessity. From ensuring customer satisfaction to optimizing cash flow, effective inventory control is crucial in achieving long-term success. Here's why:

1. Avoiding Stockouts and Overstocking

Imagine losing a sale because you're out of stock of a popular product or having shelves overflowing with unsold items, eating away at your capital. Efficient inventory management helps you find the sweet spot between these two extremes. By accurately forecasting demand, optimizing ordering processes, and tracking stock levels, you can minimize stockouts that frustrate customers and avoid overstocking, which ties up valuable resources.

2. Streamlined Operations and Cost Savings

Efficient inventory management leads to streamlined operations throughout your business. The benefits ripple across various aspects, from reduced warehousing costs and minimized waste to improved order fulfillment times. Additionally, you can potentially secure cost savings on bulk purchases by negotiating better deals with suppliers based on accurate demand forecasts.

3. Enhanced Customer Satisfaction

Imagine a customer returning to your store only to find the desired item out of stock. The disappointment can be detrimental to your brand image. Efficient inventory management ensures you have the right products available when customers need them, leading to higher customer satisfaction, repeat business, and positive brand perception.

4. Improved Decision-Making and Agility

Real-time data on your inventory levels empowers you to make informed decisions about purchasing, pricing, and product offerings. This data can also help you identify trends and adapt to changing market demands with greater agility, giving you a competitive edge.

5. Reduced Risk and Improved Profitability

Inefficient inventory management can lead to various risks, such as product damage, expiration, and theft, which can significantly impact your bottom line. By implementing robust inventory control measures, you can mitigate these risks, optimize your resources, and improve your profitability.

Investing in efficient inventory management is not just about keeping track of your stock; it's about gaining control over a critical aspect of your business. By embracing effective inventory management practices, you can navigate the complexities of the market with greater confidence, optimize your operations, and pave the way for sustainable business growth.

Challenges of Small Business Inventory Management

While the importance of understanding how to track inventory is undeniable for any business, small businesses face a unique set of challenges in this realm. Operating with limited resources and often tighter margins for error, they navigate a complex landscape where inaccuracy and inefficiency can significantly impact. Here are some key challenges small businesses face when it comes to inventory management:

1. Resource Constraints

Small businesses often have limited manpower and financial resources, making it difficult to dedicate a team member solely to inventory management. This can lead to inconsistent tracking, manual processes, and an increased risk of human error.

2. Lack of Sophisticated Systems

Implementing advanced inventory management software can be cost-prohibitive for small businesses. They may rely on manual spreadsheets or basic software, which can be inefficient and prone to errors when dealing with large or complex inventories.

3. Fluctuating Demand

Small businesses, especially those in their initial stages, may face unpredictable demand patterns when they manage inventory well. This makes it challenging to accurately forecast how much stock to keep on hand, potentially leading to stockouts or overstocking.

4. Limited Storage Space

Small businesses often have limited storage space compared to larger businesses. This necessitates optimizing space utilization and carefully managing inventory levels to avoid stockpiling and ensure efficient product flow.

5. Keeping Up with Technology

Inventory management is constantly evolving, with new technologies and software solutions emerging frequently. Staying updated with these advancements while navigating limited resources can challenge small businesses.

Despite these challenges, effective inventory management remains crucial for thriving small businesses. By embracing innovative solutions, leveraging technology strategically, and adopting efficient practices, small businesses can overcome these hurdles and achieve optimal inventory control.

The Basics of How to Manage Inventory

Whether running a small retail store or managing an online business, manage inventory is a fundamental skill that directly impacts your success. It's the process of tracking, organizing, and controlling the stock on hand, ensuring you have the right products in the right quantities at the right time. Here's a breakdown of the basics:

1. Setting Up Your System

The first step is to choose an inventory management system. This could be a simple spreadsheet, free or paid inventory management software, or a combination. Regardless of the method, your system should allow you to track:

- Product details. Name, description, code, etc.

- Stock levels. Quantity of each product on hand

- Purchase history. Record of past purchases, including dates, quantities, and costs

- Sales history. Record of product sales, including dates, quantities, and revenue

2. Taking Inventory

This involves physically counting your stock regularly to ensure accuracy and identify any discrepancies between your system and actual inventory levels. The frequency of inventory counts depends on factors like the type of products you sell, your sales volume, and your risk tolerance.

3. Establishing Minimum and Maximum Stock Levels

- Minimum stock level (min level). The lowest stock level you're comfortable having before placing a new order. Reaching this level triggers a reorder to avoid stockouts.

- Maximum stock level (max level). The highest stock level you want to maintain, considering storage space limitations and the risk of overstocking.

4. Implementing Ordering Systems

- Reorder point. The stock level at which you should place a new order to ensure you don't run out of stock before the new order arrives. This is calculated based on your lead time (time it takes to receive new stock) and average daily/weekly sales.

- Order quantity. The amount you order each time, considering factors like demand, storage space, and quantity discounts suppliers offer.

5. Utilizing Technology

Explore inventory management software that can streamline and automate various tasks, such as:

- Automatic ordering. Software can automatically generate purchase orders when stock levels reach the reorder point.

- Real-time data. Get instant updates on stock levels, sales data, and reorder points.

- Inventory forecasting. Utilize historical data to predict future demand and optimize stock levels.

Remember:

- Regularly review and update your inventory data.

- Train your staff on inventory management procedures.

- Conduct regular audits to ensure accuracy and identify potential issues.

By following these basic steps and adapting them to your specific needs, you can establish a solid foundation for effective inventory management, paving the way for a smoother operation, improved customer satisfaction, and increased profitability.

Implementing Effective Inventory Tracking Systems

Small business owners often struggle with managing inventory effectively, but choosing the right inventory management software can make a world of difference. With many options available, selecting a system that aligns with your specific needs and budget is crucial. Look for software that offers real-time tracking, automated reordering, and integration with e-commerce platforms to streamline your small business inventory management.

Choosing the Right Inventory Management Software

When selecting an inventory management software for your small business, consider scalability, ease of use, and compatibility with your existing systems. Look for solutions that offer customizable dashboards for quick insights into stock levels and sales trends. Additionally, prioritize user-friendly interfaces and robust customer support to ensure a smooth transition and ongoing support for managing your inventory efficiently.

Streamlining Inventory Processes for Small Businesses

Streamlining inventory processes is essential for small businesses looking to optimize their operations. Implementing barcode scanning and RFID technology can help automate data entry and reduce human error in managing inventory. By leveraging these tools, you can enhance accuracy in tracking stock levels, minimize manual labor, and improve overall efficiency in handling inventory tasks.

Leveraging Technology for Optimal Inventory Control

In today's digital age, technology offers numerous opportunities for small businesses to optimize inventory control. Embrace cloud-based solutions that provide real-time visibility into your stock levels from anywhere. By integrating technology when you manage inventory, you can gain better control over your supply chain, reduce carrying costs, and make informed decisions to drive business growth.

Now that we've covered the importance of choosing the right inventory management software and streamlining processes through technology integration, let's move on to strategies for optimizing your small business's inventory in the next section.

Inventory Optimization Strategies

Forecasting Demand for Better Inventory Planning

Forecasting demand is a crucial aspect of small business inventory management. Businesses can accurately predict future demand and adjust their inventory levels by analyzing sales trends and customer behavior. This proactive approach ensures that businesses are well-prepared to meet customer needs while minimizing excess stock and storage costs.

Minimizing Stockouts and Overstock Situations

Effective inventory management involves finding the delicate balance between having enough stock to meet customer demand without overstocking items that may become obsolete. By closely monitoring sales data and adjusting reorder points, businesses can minimize the risk of stockouts while also avoiding the costs associated with excess inventory.

Maximizing Warehouse Efficiency for Improved Inventory Management

Maximizing warehouse efficiency is essential for small business inventory management. Businesses can reduce operational costs and improve overall inventory control by organizing storage areas, implementing efficient picking processes, and optimizing layout design. This ensures that items are easily accessible when needed, leading to faster order fulfillment and increased customer satisfaction.

By implementing these inventory optimization strategies, small businesses can effectively manage their inventory levels to meet customer demand while minimizing unnecessary costs associated with overstock situations or inefficient warehouse operations.

Best Practices: M

anage Inventory

Utilizing RFID and barcode technology is a game-changer for small business inventory management. These tools enable you to track inventory in real-time, minimize human error, and streamline the entire process. By implementing these technologies, you can efficiently manage inventory and ensure accurate stock levels.

Utilizing RFID and Barcode Technology

By adopting RFID and barcode technology, small businesses can streamline their inventory management processes. These tools allow for accurate tracking of products from when they enter the warehouse to when they are sold. With this level of precision, businesses can effectively manage inventory levels, reduce stockouts, and improve overall operational efficiency.

Adopting Just-in-Time Inventory Management

Just-in-time (JIT) inventory management is a strategic approach that involves keeping only enough stock on hand to meet immediate demand. This practice helps small businesses minimize excess inventory holding costs while ensuring that products are readily available when needed. By adopting JIT principles, businesses can optimize cash flow and manage inventory more efficiently.

Implementing Cycle Counting for Accurate Inventory Control

Cycle counting is a method of regularly auditing a small portion when you manage inventory to ensure accuracy. By implementing this practice, businesses can identify discrepancies in stock levels early on and take corrective action promptly. This approach allows for accurate inventory control without disrupting day-to-day operations.

By incorporating these best practices into your small business's inventory management strategy, you can effectively track and manage inventory while minimizing costs and maximizing efficiency.

Employee Training and Communication in Inventory Management

Importance of Training Staff for Effective Inventory Handling

Small businesses must invest in training their staff on how to manage inventory efficiently. Proper training ensures that employees understand the importance of accurate inventory tracking and have the necessary skills to handle inventory effectively.

Establishing Clear Communication Channels for Inventory Updates

Clear communication channels are essential for seamless inventory management. Small businesses should implement regular team meetings, use digital communication tools, and establish a protocol for reporting inventory updates to ensure that everyone is on the same page when you manage inventory.

Encouraging Employee Accountability in Inventory Management

Encouraging employee accountability is key to successful inventory management. By setting clear expectations and holding employees responsible for their roles in managing inventory, small businesses can create a culture of ownership and reliability within their teams.

Strikingly Simplifies Inventory Management for Growing Businesses

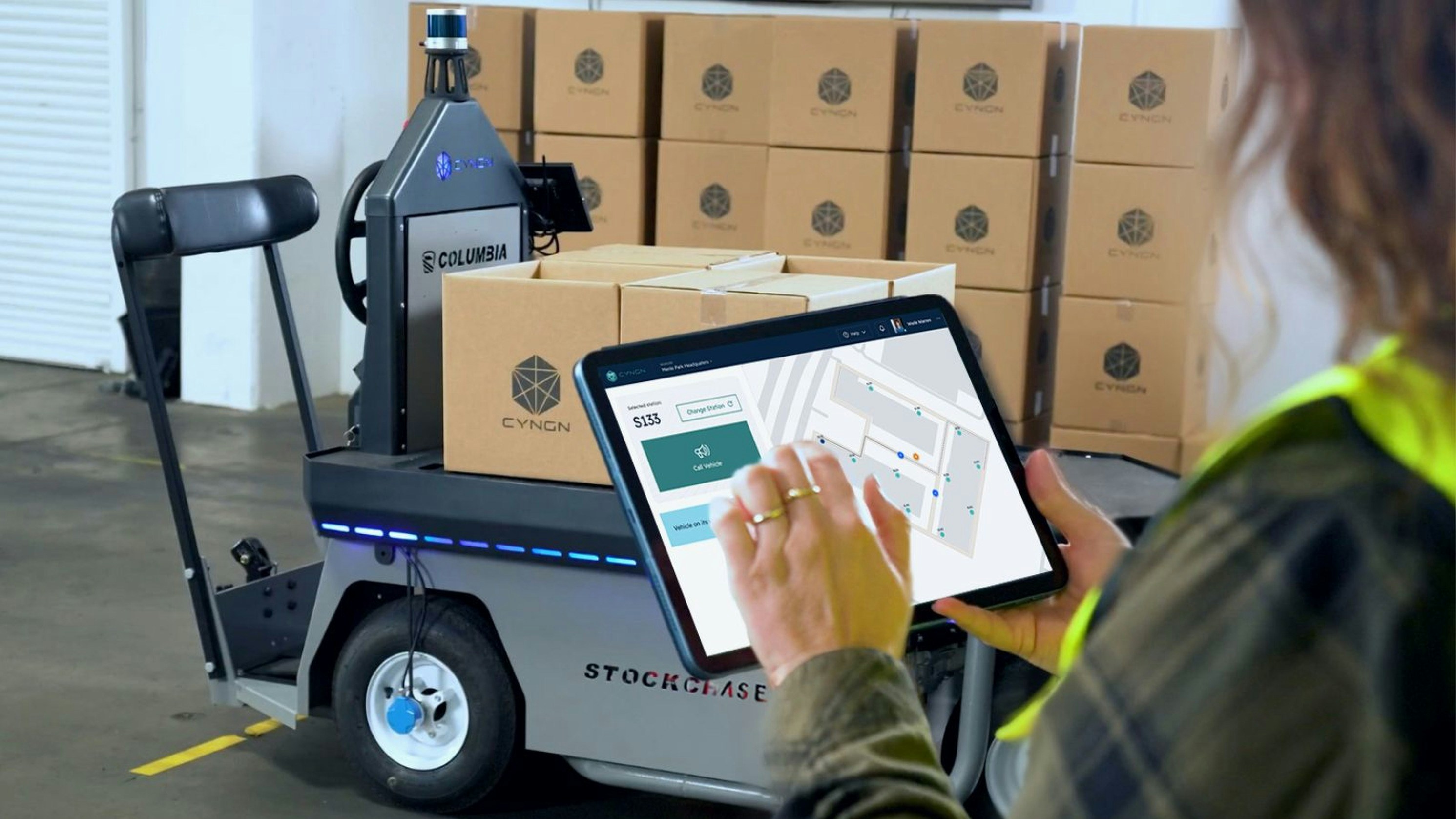

Image taken from Strikingly

When small businesses manage inventory, it can feel like a constant juggling act. Keeping track of stock levels, ensuring product availability, and preventing stockouts can be a complex and time-consuming process. Fortunately, Strikingly's eCommerce features offer a user-friendly and efficient solution to streamline inventory management, empowering small businesses to focus on what they do best - selling.

Here's how Strikingly simplifies inventory management for your business:

1. Effortless Product Listing and Tracking

Strikingly allows you to easily add, edit, and remove products from your online store. Each product listing can be customized to include essential details like descriptions, images, variants, and pricing. This comprehensive information makes it easy to track your inventory at a glance and avoid confusion for you and your customers.

2. Real-Time Inventory Updates

With Strikingly, you can manage your inventory in real time. As customers place orders, stock levels automatically update, reflecting the remaining quantity available for purchase. This eliminates the risk of overselling and ensures that customers are always presented with accurate information about product availability.

3. Low-Stock Alerts and Automated Notifications

Strikingly can be configured to send you automatic notifications when your stock levels reach a predefined minimum threshold. This timely low-stock alert allows you to replenish your inventory before you run out of stock, preventing potential lost sales and customer frustration.

4. Simple Order Management and Tracking

Strikingly's intuitive order management system lets you view and track all your orders in one place. You can easily monitor order status, fulfillment details, and customer information, streamlining the entire sales process. Additionally, you can update customers with order status notifications, keeping them informed throughout the fulfillment process.

5. Integration with Multiple Payment Gateways

Strikingly integrates with various popular payment gateways, allowing you to accept secure online payments from your customers. This streamlines the checkout process and eliminates manual order handling, reducing the risk of errors and delays.

Beyond these core features, Strikingly offers additional benefits:

- Mobile-friendly design. Ensure your online store looks great and functions flawlessly on all devices, making it easy for customers to browse and purchase products anytime, anywhere.

- Free plan available. Experiment with Strikingly's basic features for free before committing to a paid plan.

- Affordable pricing. Strikingly offers a paid plan that fits your business needs and budget, making it an accessible solution for small businesses.

By leveraging Strikingly's user-friendly interface, automated features, and integration capabilities, small businesses can take control of their inventory management and focus on growing their online presence. Strikingly empowers you to spend less time managing stock and more time nurturing your business.

Embrace Innovation in Inventory Control

Mastering the art of small business inventory management is crucial for success. By implementing proven inventory management techniques and embracing innovation in inventory control, businesses can streamline operations and maximize profitability. The future of inventory management lies in leveraging technology and optimizing warehouse efficiency to manage inventory more effectively.

Achieving Success with Proven Inventory Management Techniques

Small businesses can achieve success in managing their inventory by following best practices such as utilizing RFID and barcode technology, adopting just-in-time inventory management, and implementing cycle counting for accurate inventory control. These techniques help businesses minimize stockouts, reduce overstock situations, and optimize their warehouse operations for improved efficiency.

Embracing innovation in inventory control involves leveraging advanced technology solutions such as Strikingly's user-friendly platform for inventory tracking and e-commerce integration. By streamlining inventory processes and using the right management software, businesses can effectively track and manage their inventory to meet customer demand while minimizing costs.

The Future of Inventory Management

The future of inventory management is centered around leveraging technology for optimal control, forecasting demand for better planning, and maximizing warehouse efficiency. As businesses continue to adapt to changing consumer behaviors and market trends, the need for efficient small business inventory management will only grow stronger.